A. Overall Description of Pain Points in Enterprise Equipment Inspection

Enterprise equipment inspection often encounters various difficulties in actual operations. These challenges not only affect the efficiency of equipment inspection but also pose risks to the normal operation of the enterprise. The following are the main pain points:

- High Cost of Paper - based Management: The customization, printing, and mailing of paper documents consume a significant amount of time and money. This not only increases the financial burden on the enterprise but also is not environmentally friendly.

- Inefficient Document Management: Storing paper documents requires a large amount of space, and it is time - consuming and labor - intensive to search, use, and analyze them. This inefficiency can lead to delays in decision - making and problem - solving.

- Poor Communication Efficiency: Most work is communicated orally, making it difficult to accurately and timely obtain task details and progress, especially in equipment repair. Information inaccuracies can cause maintenance workers to make multiple trips to the site, delaying the repair process.

- Unsmooth Workflow: Some paper - based document approvals and transmissions need to be submitted by employees themselves, which is easily affected by factors such as the leader's business trips or meetings, resulting in slow process advancement.

In summary, these pain points in equipment inspection have a negative impact on the overall operation of the enterprise, reducing efficiency and increasing costs.

B. Case Analysis of Pain Points

1. High Cost of Paper - based Management

In the traditional equipment inspection process, many enterprises rely on paper - based documents for record - keeping and communication. For example, in a manufacturing enterprise, inspection reports are printed on paper, and each inspection requires a new set of forms. The cost of paper, printing, and distribution can be substantial over time.

For instance, Tesaia (Ningbo) Mechanical Manufacturing Co., Ltd. used to spend a large amount of money on the customization, printing, and mailing of paper documents. This additional cost put pressure on the company's budget. The paper - based management method was not only expensive but also time - consuming, affecting the overall efficiency of the enterprise.

2. Inefficient Document Management

Storing and managing paper documents is a headache for many enterprises. In a large - scale enterprise with a large number of equipment, storing inspection reports, maintenance records, and other documents requires a dedicated storage space. When it comes to searching for a specific document, employees may need to spend a long time rummaging through file cabinets.

Take Tesaia (Ningbo) as an example again. The company had a large number of paper documents related to equipment inspection and maintenance. When they needed to find a specific maintenance record, it often took a long time to locate the relevant file. This inefficiency affected the timeliness of decision - making and problem - solving.

3. Poor Communication Efficiency

In the equipment inspection and repair process, communication plays a crucial role. However, oral communication often leads to information loss and inaccuracies. In a factory, when an equipment failure occurs, the on - site staff may not be able to accurately describe the problem to the maintenance workers. As a result, the maintenance workers may not be fully prepared when they arrive at the site, leading to multiple trips and delays in the repair process.

In Tesaia (Ningbo), many work contents were communicated orally. In the case of equipment repair, the information transmitted was often incomplete or inaccurate. This led to maintenance workers having to make multiple trips to the site to apply for spare parts, and the equipment supervisor could not timely understand the work tasks and progress of the maintenance workers, making it difficult to arrange work effectively.

4. Unsmooth Workflow

The approval and transmission of paper - based documents are often subject to various restrictions. In an enterprise, when an inspection report needs to be approved, the employee has to personally submit the document to the relevant leader. If the leader is on a business trip or in a meeting, the approval process will be delayed.

In Tesaia (Ningbo), some paper - based document approvals and transmissions needed to be handled by employees themselves. This was easily affected by the leader's schedule, resulting in slow process advancement and affecting the overall efficiency of equipment inspection and maintenance.

C. Product Introduction

1. Traditional Equipment Inspection Software

Traditional equipment inspection software usually provides basic functions such as inspection task assignment, data recording, and report generation. It can help enterprises digitize the inspection process to a certain extent, reducing the use of paper documents. However, these software often have limitations. For example, they may lack flexibility in customization, and it is difficult to adapt to the unique needs of different enterprises. In addition, the data analysis function is relatively weak, making it difficult to provide in - depth insights for decision - making.

2. IoT - enabled Equipment Inspection Systems

IoT - enabled equipment inspection systems use sensors and Internet of Things technology to collect real - time data from equipment. This allows enterprises to monitor equipment status in real - time and detect potential problems in advance. However, the implementation of these systems often requires a large amount of hardware investment and complex network infrastructure. Moreover, the data security and privacy issues associated with IoT devices need to be carefully addressed.

3. No - code Platform: Wingent

Wingent is a no - code platform that can effectively solve the pain points in enterprise equipment inspection. It offers a range of features and capabilities that can optimize the inspection process and improve efficiency.

D. How Wingent Solves the Pain Points in Equipment Inspection

Wingent is a powerful no - code platform that has the ability to comprehensively solve the pain points in enterprise equipment inspection. Here's how it works:

1. Standardized Inspection

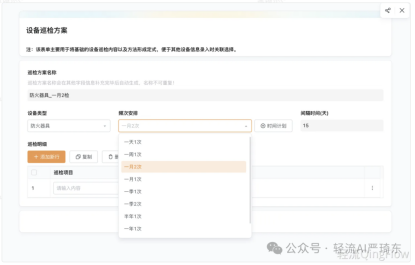

Wingent allows enterprises to customize standardized inspection templates according to their equipment characteristics and management requirements using professional form design tools. In the template, rich conditional branch logic is set. When the equipment parameters exceed the normal range, the system automatically triggers the repair process, realizing intelligent inspection.

Wingent allows enterprises to customize standardized inspection templates according to their equipment characteristics and management requirements using professional form design tools. In the template, rich conditional branch logic is set. When the equipment parameters exceed the normal range, the system automatically triggers the repair process, realizing intelligent inspection.

For example, a power enterprise adopted this standardized inspection mode. Before using Wingent, the equipment miss - inspection rate was relatively high due to human negligence. After using Wingent, the equipment miss - inspection rate was reduced by 70%. This shows that Wingent's standardized inspection process can ensure that each piece of equipment is inspected in a timely and comprehensive manner, effectively improving the stability and reliability of equipment operation.

2. Clear Responsibility Assignment

Based on the actual organizational structure and business process of the enterprise, Wingent clearly defines the responsibilities of each department and position in equipment management. By setting task assignment rules and approval processes, all tasks in equipment management can be accurately assigned to specific personnel.

Based on the actual organizational structure and business process of the enterprise, Wingent clearly defines the responsibilities of each department and position in equipment management. By setting task assignment rules and approval processes, all tasks in equipment management can be accurately assigned to specific personnel.

For instance, in the equipment repair application process, the system automatically pushes the task to the corresponding maintenance personnel, avoiding the problem of responsibility shifting caused by unclear responsibilities. This ensures that each task has a clear owner, improving the efficiency of problem - solving.

3. Real - time Data Tracking

The mobile application of Wingent plays a key role in real - time data tracking. Inspectors can use the mobile device to scan the code for inspection. The equipment positioning and photo watermark anti - tampering technology ensure the authenticity and reliability of the inspection data.

The mobile application of Wingent plays a key role in real - time data tracking. Inspectors can use the mobile device to scan the code for inspection. The equipment positioning and photo watermark anti - tampering technology ensure the authenticity and reliability of the inspection data.

Once the equipment operation parameters are abnormal, the system automatically triggers a maintenance work order and accurately pushes it to the responsible person. An electronics manufacturing enterprise used Wingent's mobile inspection function. Before that, it took an average of 2 hours to discover equipment anomalies. After using Wingent, this time was significantly reduced to within 15 minutes, greatly improving the timeliness of equipment repair and effectively ensuring the smooth progress of production.

4. Complete Management System

Wingent helps enterprises improve the equipment management system by implementing the one - thing - one - code concept. Each piece of equipment is assigned a unique QR code or barcode, and a detailed and accurate equipment file is established. From the basic information input at the time of equipment purchase, such as equipment model, specifications, supplier, and purchase price, to the upload of equipment acceptance reports and user manuals, all information can be completely presented in the equipment file.

Wingent helps enterprises improve the equipment management system by implementing the one - thing - one - code concept. Each piece of equipment is assigned a unique QR code or barcode, and a detailed and accurate equipment file is established. From the basic information input at the time of equipment purchase, such as equipment model, specifications, supplier, and purchase price, to the upload of equipment acceptance reports and user manuals, all information can be completely presented in the equipment file.

This makes every link in equipment management traceable, standardizing the entire life - cycle management process of equipment and effectively solving the operational chaos caused by the imperfect system. For example, a large - scale mechanical manufacturing enterprise used to spend a lot of time searching for equipment maintenance records in a large number of paper files. After using Wingent's one - thing - one - code system, maintenance workers can obtain the required information within a few seconds by scanning the QR code, greatly improving work efficiency.

5. Enhanced Maintenance and Inspection

Wingent optimizes the equipment inspection work. Inspectors only need to carry a mobile phone or tablet to quickly complete the inspection task on - site. Through the pre - set inspection template, the system reminds inspectors to follow the specified time, route, and inspection items for inspection and records the inspection data in real - time.

Wingent optimizes the equipment inspection work. Inspectors only need to carry a mobile phone or tablet to quickly complete the inspection task on - site. Through the pre - set inspection template, the system reminds inspectors to follow the specified time, route, and inspection items for inspection and records the inspection data in real - time.

Once an equipment anomaly is found, the inspector can immediately take a photo, upload it, and submit a problem report, greatly improving the efficiency of preventive maintenance, detecting potential problems in a timely manner, and reducing the probability of sudden equipment failures.

In summary, Wingent effectively solves the pain points in enterprise equipment inspection through standardized inspection, clear responsibility assignment, real - time data tracking, a complete management system, and enhanced maintenance and inspection. It helps enterprises improve equipment inspection efficiency, reduce costs, and ensure the stable operation of equipment.

Enterprise equipment inspection is a crucial part of enterprise operation, and the pain points in this process have a significant impact on the efficiency and cost of the enterprise. By understanding the common pain points and solutions, enterprises can make more informed decisions. Wingent, as an advanced no - code platform, provides a comprehensive and effective solution to these pain points, enabling enterprises to optimize their equipment inspection processes and improve overall operational efficiency.

Reference: [1] 生产设备管理:一全、二实、三预、四驱、五联 https://mp.weixin.qq.com/s/slh_SRaDdwl07yYTLHcPUg [2] 3000字把怎么做设备档案、巡检、报修、保养讲清楚了 https://mp.weixin.qq.com/s/uxhoGdjN9JrN3XGpw6XDMA