A. Overall Description of the Pain Points in Enterprise Order Management

Enterprise order management is fraught with numerous challenges that can impede business growth and operational efficiency. These pain points often stem from outdated processes, lack of integration, and poor data management.

- Inefficient Process Flow: Manual order processing is time - consuming and error - prone. It involves multiple steps, such as data entry, approval, and tracking, which can lead to delays and mistakes.

- Lack of Integration: Different departments within an enterprise, such as sales, production, and logistics, may use separate systems that do not communicate effectively. This lack of integration results in information silos, making it difficult to have a holistic view of the order status.

- Data Inaccuracy: Inaccurate order data, such as incorrect product information, quantities, or customer details, can lead to wrong shipments, customer dissatisfaction, and financial losses.

- Poor Communication: Miscommunication between departments and with customers can cause delays in order processing, missed deadlines, and misunderstandings.

In summary, these pain points create a complex web of challenges that hinder the smooth operation of enterprise order management, leading to inefficiencies, increased costs, and reduced customer satisfaction.

B. Case Analysis of the Pain Points in Enterprise Order Management

1. Inefficient Process Flow

Inefficient process flow is a significant pain point in enterprise order management. In many traditional enterprises, order processing relies heavily on manual labor, which is not only time - consuming but also prone to errors. For example, when a salesperson receives an order, they have to manually enter the order details into a system, which may involve multiple forms and steps. Then, the order needs to be approved by different levels of management, and each approval step may take time. This manual process can lead to significant delays, especially when there are a large number of orders.

For instance, a manufacturing company used to rely on a paper - based order processing system. When an order came in, the sales team had to fill out multiple forms and send them to different departments for approval. This process often took several days, and sometimes, important information was lost or misinterpreted during the transfer. As a result, production was delayed, and customers were unhappy with the long lead times.

2. Lack of Integration

The lack of integration between different departments' systems is another major pain point. In an enterprise, the sales department may use a customer relationship management (CRM) system, the production department may use a manufacturing resource planning (MRP) system, and the logistics department may use a separate inventory management system. These systems often do not communicate with each other, creating information silos.

Take a retail enterprise as an example. The sales department uses a CRM system to manage customer orders, but this system is not integrated with the inventory management system used by the logistics department. As a result, the sales team may promise customers products that are out of stock, leading to customer dissatisfaction. Also, the production department may not have real - time information about the orders, which can lead to over - or under - production.

3. Data Inaccuracy

Data inaccuracy can have a profound impact on enterprise order management. Incorrect order data can lead to wrong shipments, returns, and customer complaints. For example, if the product information in the order is incorrect, such as the wrong size, color, or model, the customer will receive the wrong product.

A consumer goods company once faced a problem with data inaccuracy. The sales team entered incorrect product quantities in the order system, which led to over - production. The excess inventory had to be stored at a high cost, and the company also had to offer discounts to clear the stock, resulting in financial losses.

4. Poor Communication

Poor communication is a common pain point that can disrupt the entire order management process. Miscommunication between departments can lead to misunderstandings about order requirements, delivery dates, and customer expectations.

A service - based enterprise experienced this pain point when the sales team promised a quick delivery to a customer without consulting the operations team. The operations team was not aware of this promise and could not meet the delivery deadline. This led to a disappointed customer and potential damage to the company's reputation.

C. Product Introduction for Solving Order Management Pain Points

1. CRM Systems

CRM systems are designed to manage customer relationships and can play a crucial role in order management. They allow sales teams to track customer interactions, manage leads, and convert them into orders. CRM systems can also provide real - time visibility into customer information, such as purchase history and preferences, which helps in personalized order processing.

However, traditional CRM systems may have limitations. They may not be fully integrated with other enterprise systems, such as production and logistics. This can still lead to information gaps and inefficiencies. For example, a CRM system may show that an order has been placed, but it may not provide real - time information about the production status or delivery schedule.

2. ERP Systems

Enterprise Resource Planning (ERP) systems integrate various business processes, including order management, production, finance, and human resources. They provide a unified platform for data management and process automation. ERP systems can help eliminate data silos by ensuring that all departments have access to the same information.

But ERP systems are often complex and expensive to implement. They may require significant customization to fit the specific needs of an enterprise. Also, the implementation process can be time - consuming, and there may be a steep learning curve for employees.

3. No - code Platform: Wingent

Wingent is a no - code platform that can effectively address the pain points in enterprise order management. It offers a simple and intuitive way to build customized order management systems without the need for coding skills.

D. How Wingent Solves the Pain Points in Enterprise Order Management

Wingent is a powerful no - code platform that is specifically designed to address the pain points in enterprise order management. It offers a range of features that can streamline the order management process and improve operational efficiency.

1. Streamlining the Process Flow

Wingent enables enterprises to automate their order processing workflows. With its drag - and - drop interface, businesses can easily create custom workflows that mimic their actual order processing steps. For example, when an order is received, Wingent can automatically route it to the appropriate departments for approval, and once approved, it can trigger the production and delivery processes.

This automation significantly reduces the time and effort required for manual order processing. A company that implemented Wingent for order management saw a 30% reduction in order processing time. Workers no longer need to spend hours on data entry and approval chasing, allowing them to focus on more value - added tasks.

2. Integration of Systems

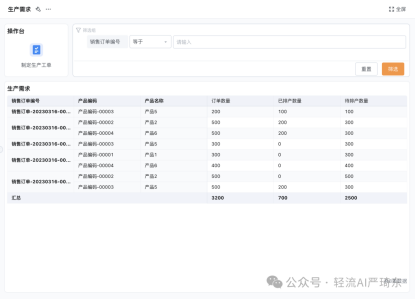

One of the key strengths of Wingent is its ability to integrate different systems within an enterprise. It can connect with existing CRM, MRP, and inventory management systems, breaking down information silos. This integration allows for real - time data sharing between departments, providing a comprehensive view of the order status.

For example, when an order is updated in the CRM system, Wingent can automatically synchronize the data with the production and logistics systems. This ensures that all departments are working with the most up - to - date information, reducing the chances of miscommunication and errors.

3. Ensuring Data Accuracy

Wingent helps maintain data accuracy by providing validation rules and data cleansing features. When an order is entered into the system, it can check for errors, such as incorrect product codes or quantities, and prompt the user to correct them.

Moreover, Wingent can store historical order data in a structured way, making it easy to track and analyze. This data accuracy helps in making informed business decisions and reduces the risk of financial losses due to incorrect orders.

4. Improving Communication

Wingent enhances communication within the enterprise and with customers. It provides a centralized platform where all stakeholders can access order information, leaving comments, and track progress. For internal communication, departments can easily collaborate on an order, sharing updates and resolving issues in a timely manner.

For customer communication, Wingent can send automated order status updates, such as order confirmation, shipping notifications, and delivery confirmations. This improves customer satisfaction by keeping them informed throughout the order process.

In conclusion, Wingent effectively addresses the pain points in enterprise order management through its automation, integration, data accuracy, and communication - enhancing features. It provides a cost - effective and efficient solution for enterprises looking to streamline their order management processes.

Enterprise order management is a critical aspect of business operations, and the pain points associated with it can have far - reaching consequences. Inefficient process flow, lack of integration, data inaccuracy, and poor communication are common challenges that many enterprises face. However, with the right technological solutions, such as Wingent, these pain points can be effectively eliminated. Wingent offers a comprehensive set of features that automate processes, integrate systems, ensure data accuracy, and improve communication. By implementing Wingent, enterprises can streamline their order management, enhance operational efficiency, and ultimately boost customer satisfaction and business profitability.

Reference

[1]生产计划、排产调度、现场管控、质量管理怎么做?一文看懂生产全流程管理 https://mp.weixin.qq.com/s/DR2qqMLPuA4ADOOJvtuLPw [2]5000字详解生产质量管理:供应链、工序、检验、溯源、工具、激励、文化 https://mp.weixin.qq.com/s/TSQHoUsDtlWldBNkiUFbIw