A. Overall Description of Key Challenges in Enterprise Production Management

Enterprise production management is fraught with difficulties that impede smooth operations and growth. These challenges stem from various aspects of the production process and management structure.

- Outdated Systems: Many enterprises still rely on legacy systems that are unable to keep up with the dynamic nature of modern production. These systems lack the flexibility to adapt to changing business requirements and often result in inefficiencies.

- Poor Data Management: Manual data collection and analysis are time - consuming and error - prone. Inaccurate or incomplete data can lead to wrong decisions, such as over - or under - production.

- Communication Barriers: Silos between different departments, such as production, sales, and logistics, can cause misalignment in goals and processes. This leads to delays, misunderstandings, and a lack of coordination.

- Inefficient Resource Allocation: Without proper planning and real - time data, enterprises may allocate resources inefficiently, leading to underutilization of assets or over - staffing in certain areas.

In summary, these pain points in enterprise production management result in reduced productivity, increased costs, and a negative impact on customer satisfaction.

B. Pain Point Case Analysis

1. Outdated Systems

Outdated systems are a significant pain point in enterprise production management. In the production environment, legacy systems often lack the ability to integrate with new technologies, which restricts the enterprise's ability to innovate and improve efficiency. For example, an old - fashioned production scheduling system may not be able to adjust quickly to changes in order volume or product specifications. For instance, the Tianjin Daqiaodao Food Company, a well - known cold - food manufacturer, used to rely on an old business system. This system could only handle partial business functions, and employees couldn't access product price information on mobile devices, making mobile work impossible. As a result, the company faced difficulties in responding promptly to market changes and customer demands.

2. Poor Data Management

Poor data management can have a severe impact on production management. In a manufacturing setting, inaccurate or delayed data can lead to production bottlenecks. For example, if the inventory data is not updated in real - time, the production department may run out of raw materials, causing production to halt. Take a furniture factory as an example. In the past, the factory used paper - based work orders and Excel spreadsheets for data management. Paper work orders were easily lost, and Excel spreadsheets were difficult to manage effectively. When a quality problem occurred, it was almost impossible to trace the root cause due to the lack of accurate historical data. This led to increased costs and a damaged reputation.

3. Communication Barriers

Communication barriers between departments can disrupt the production process. In a large - scale manufacturing enterprise, the production department may not be aware of the sales department's new orders or customer requirements in a timely manner. This can result in over - production of unpopular products or under - production of high - demand items. For example, in a machinery manufacturing company, the production and R & D departments often worked in isolation. The R & D department developed new products without fully considering the production capabilities and constraints, which led to long production cycles and high costs.

4. Inefficient Resource Allocation

Inefficient resource allocation can waste valuable resources and reduce profitability. In a production plant, improper allocation of labor, equipment, and materials can lead to under - utilization of assets. For example, if a machine is over - utilized while others are idle, it can lead to increased maintenance costs and a shorter lifespan of the over - used machine. For instance, a textile factory may allocate too many workers to a particular production line while neglecting others. This can result in an imbalance in production output and a decrease in overall efficiency.

C. Product Introduction

1. ERP Systems

Enterprise Resource Planning (ERP) systems are comprehensive software solutions that integrate various business processes, including production, finance, human resources, and supply chain management. These systems provide a centralized database that allows for real - time data sharing and collaboration among different departments. By using an ERP system, enterprises can streamline their production processes, improve inventory management, and enhance decision - making. However, ERP systems can be complex and expensive to implement, and they may require significant customization to fit the specific needs of an enterprise.

2. MES Systems

Manufacturing Execution Systems (MES) focus on the real - time monitoring and control of the production process. They collect data from the shop floor, such as machine status, production progress, and quality control results. MES systems can help enterprises optimize production schedules, reduce downtime, and improve product quality. Nevertheless, MES systems may not be able to integrate well with other business systems, and they often require a high level of technical expertise to operate.

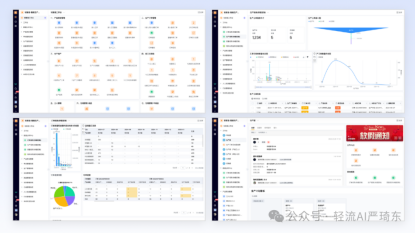

3. No - code Platform: Wingent

Wingent is a no - code platform that can effectively address the pain points in enterprise production management. It offers a flexible and customizable solution without the need for extensive coding knowledge.

D. How Wingent Solves the Pain Points in Enterprise Production Management

Wingent is a powerful no - code platform that can effectively tackle the key challenges in enterprise production management. It offers a comprehensive set of features and capabilities to streamline operations and improve efficiency.

1. Eliminating Outdated Systems

Wingent can replace legacy systems with its modern and flexible architecture. It allows enterprises to build customized applications that can integrate with existing systems and new technologies. For example, Daqiaodao replaced its old business system with Wingent and integrated it with DingTalk. This enabled employees to access information on mobile devices, achieving seamless mobile work.

2. Improving Data Management

Wingent provides a centralized data management system that ensures data accuracy and real - time availability. Workers can use mobile devices to scan work orders or product QR codes to quickly report production data, such as completed quantities and working hours. This data is automatically updated in the system, providing managers with accurate and up - to - date information. For example, in a furniture factory, after implementing Wingent, the problem of data loss and difficult retrieval was solved. Electronic work orders are permanently stored, and historical data can be easily accessed.

3. Breaking Communication Barriers

Wingent facilitates seamless communication among different departments. It allows for the creation of workflows that can be shared and accessed by all relevant parties. For example, in a manufacturing enterprise, the production, sales, and logistics departments can use Wingent to share information and coordinate activities in real - time. This reduces misunderstandings and delays, improving overall efficiency.

4. Optimizing Resource Allocation

Wingent helps enterprises optimize resource allocation by providing real - time data and analytics. Managers can use the system to monitor resource usage, such as machine utilization and labor hours. Based on this information, they can make informed decisions to allocate resources more efficiently. For example, in a production plant, Wingent can analyze production data to identify under - utilized machines and re - allocate tasks to improve overall productivity.

In conclusion, Wingent effectively addresses the pain points in enterprise production management by providing a modern, flexible, and efficient solution. It helps enterprises improve productivity, reduce costs, and enhance competitiveness in the market.

Conclusion

In summary, the pain points in enterprise production management, such as outdated systems, poor data management, communication barriers, and inefficient resource allocation, have a significant impact on the enterprise's performance. However, with the help of advanced technological solutions like Wingent, these issues can be effectively resolved. Wingent offers a comprehensive and customizable platform that streamlines operations, enhances visibility, and improves decision - making. By adopting Wingent, enterprises can overcome production management challenges and achieve sustainable growth.

Reference: [1] 5000字详解生产质量管理:供应链、工序、检验、溯源、工具、激励、文化 https://mp.weixin.qq.com/s/TSQHoUsDtlWldBNkiUFbIw [2] 生产计划、排产调度、现场管控、质量管理怎么做?一文看懂生产全流程管理 https://mp.weixin.qq.com/s/DR2qqMLPuA4ADOOJvtuLPw [3] 2小时,我搭建了一个生产管理系统,包含排程、质量、物料、设备、报工等多模块 https://mp.weixin.qq.com/s/G6BG0ez8vV93nBS4BhbWtQ [4] 7大维度,中小制造业企业如何选择生产管理系统? https://mp.weixin.qq.com/s/pm14LCcwxlHfMKRHAgkEFQ [5] 7大维度,中小制造业企业如何选择生产管理系统? https://mp.weixin.qq.com/s/pm14LCcwxlHfMKRHAgkEFQ